Case Study: Titanium Foam for PEM Water Electrolyzers

Introduction

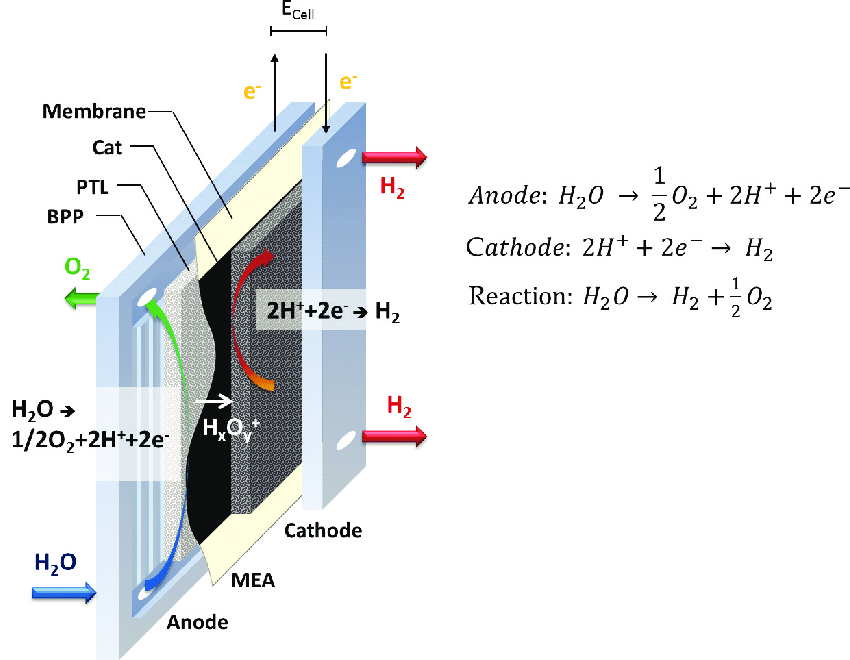

Stanford Advanced Materials (SAM), a trusted source of advanced materials and specialty metals, recently supported a university research project in the United States that required high-quality titanium foam as part of a PEM (Proton Exchange Membrane) water electrolyser.

[1]

[1]

The Challenge

The research team approached SAM with the following requirements:

- Material Suitability for PEM Research – The titanium foam had to demonstrate stability when exposed to highly acidic operating conditions that are typical with PEM electrolysers.

- Structural Integrity and Porosity – The foam had to be mechanically stable while still delivering suitable pore networks to facilitate gas diffusion and catalyst dispersion.

- Research-Scale Sample Dimensions – The test required an experimental setup and testing of a sheet of titanium foam (20 cm × 20 cm × 5 mm) in the laboratory.

The Solution

SAM's technical advisor recommended the use of TI1816 Titanium Foam, an ultra-high-quality porous titanium product widely used in energy and electrochemical applications.

SAM's titanium foam contains a naturally occurring oxide layer that protects it against corrosion under acidic environments. The supplied foam showed high surface area and open porosity, which increased catalyst utilisation while promoting effective hydrogen and oxygen release.

The Results

The research group successfully implemented SAM's titanium foam in its R&D activities involving PEM water electrolysers. The primary results were:

- Titanium Foam Validation as an Appropriate Substrate – The material demonstrated the potential to serve as an electrode support, meeting structural and corrosion-resistant requirements.

- Enhanced Research Effectiveness – The precise dimensions allowed direct integration into test assemblies without additional machining.

- Enabling Clean Energy R&D – With the procurement of titanium foam from SAM, the project continued its purpose to optimise electrolyser efficiency and hydrogen production performance.

What Is Titanium Foam?

Titanium foam is a three-dimensional, porous light metal that combines the mechanical and chemical advantages of titanium with the unique performance features of a foam structure. It is made using methods such as powder metallurgy with space-holder techniques, freeze-casting, or additive manufacturing (3D printing), which allow for control over porosity, pore size, and structural homogeneity.

Structural Features

Titanium foam typically possesses porosity in the range of 40% to 80%, and this can be adjusted according to the desired application. The pore size can be tailored from tens of microns to several millimetres, allowing for tailored mass transport characteristics. Despite being open-structured, titanium foam compressive strength and stiffness over density are very high, making it tough under load. The metal structure being continuous provides good electrical conductance and consequently is suitable as an electrode support or current collector.

Key Features

- Corrosion Resistance – The TiO₂ coating of Titanium is resistant to acid and oxidative degradation.

- High Specific Surface Area – Offers ample reaction sites to facilitate electrochemical reactions and deposition of catalysts.

- Permeability to Gas and Fluids – Pores are connected such that gas release as well as water transport can be effective.

- Low-Density Structure – Lower density compared to solid titanium but retains required strength.

- Biocompatibility – Non-toxic and compatible with biological systems, hence equally utilised in biomedical applications.

Applications of Titanium Foam

- Energy and Electrochemistry: Titanium foam serves as anode substrates, catalyst supports, and current collectors in PEM water electrolysers, as well as flow fields and gas diffusion layers in fuel cells. It is also used as conductive scaffolds in lithium-ion and solid-state batteries.

- Biomedical Engineering: Titanium foam in bone scaffolds and bone implants improves osteointegration and in dental prostheses and surgical implants due to its biocompatibility and toughness.

- Chemical Processing and Catalysis: It is applied as a catalyst support in hydrogenation and oxidation reactions and in electrochemical filters and reactors requiring corrosion resistance.

- Aerospace and Defence: Titanium foam provides lightweight, corrosion-resistant structural members and thermal management composites for aerospace applications.

Why Titanium Foam and Not Other Material?

In the selection of electrode and substrate materials for PEM water electrolysers, there are several options, but titanium foam has certain advantages:

|

Material |

Strengths |

Weaknesses / Notes |

|

Graphite Plates |

Good conductivity |

Brittle, costly to machine |

|

Stainless Steel Foams |

Low cost, easy to process |

Corrodes in acidic PEM, needs coatings |

|

Nickel Foams |

Excellent conductivity |

Unstable in acidic PEM |

|

Titanium Foam |

Corrosion-resistant, strong, conductive |

Ideal for long-term acidic PEM use |

For more information and advanced materials, please check Stanford Advanced Materials (SAM).

What Is SAM's TI1816 Titanium Foam?

TI1816 Titanium Foam is a unique porous titanium material provided by Stanford Advanced Materials. Delivered in special sheet dimensions, thicknesses, and porosity rates to meet special customer requirements, it is manufactured to high purity and structural homogeneity and is particularly suited for demanding environments such as electrolysis, catalysis, and biomedical research.

Conclusion

Through this collaboration, Stanford Advanced Materials provided tailored-made titanium foam for research in PEM water electrolysers. From meeting the project's structural and corrosion resistance requirements to providing precise dimensions, SAM established itself as a reliable collaborator for both industry and academic customers.

Reference:

[1] Lettenmeier, Philipp & Gago, Aldo & Friedrich, K.. (2017). Protective Coatings for Low-Cost Bipolar Plates and Current Collectors of Proton Exchange Membrane Electrolyzers for Large Scale Energy Storage from Renewables. 10.5772/intechopen.68528.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento