A Closer Look At Piezoelectric Crystal

Introduction

Piezoelectric crystals are a class of crystalline materials that can produce a change in charge distribution when mechanical stress is applied and can generate an electrical response under an applied electric field. Their specific properties are employed in various fields, particularly in sensor technology and energy conversion. The primary feature is that they deform or redistribute electrical charges when a mechanical load or an electric field is applied, thereby enabling the conversion between electrical and mechanical energy. As technological development proceeds, the range of applications for piezoelectric crystals has increased. Applications extend from materials in smart systems to devices for energy harvesting, providing new possibilities for industry. A detailed understanding of the characteristics and applications of piezoelectric crystals is required in order to comprehend current technological trends.

What is a Piezoelectric Crystal?

A piezoelectric crystal is a non‐centrosymmetric crystal. When mechanical force is applied, the crystal deforms, causing a relative shift of charged centres. This effect results in the appearance of positive and negative bound charges on the crystal surface. When the external force is removed, the crystal returns to its electrically neutral condition. This process is known as the piezoelectric effect.

The piezoelectric crystal possesses a polar axis with a potential difference at each end, which is defined as piezoelectricity. The amount of charge produced is directly proportional to the magnitude of the applied force. Conversely, when an electric field is applied, the crystal undergoes mechanical deformation in a specific direction; the deformation ceases when the electric field is removed. This process is referred to as the inverse piezoelectric effect, also known in technical terms as the electrostriction effect.

Examples of piezoelectric crystals include quartz (α-quartz), sphalerite, calcite, tourmaline, red zincite, GaAs, barium titanate along with its derived structure crystals, KH2PO4, NaKC4H4O6·4H2O (Rochelle salt) and sucrose.

Fig. 1 Natural Quartz Crystals

Crystallographic Structural Characteristics of Piezoelectric Crystals

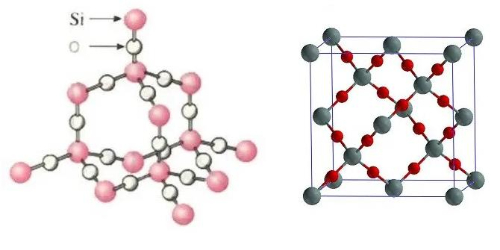

Piezoelectric crystals typically exhibit a non‐centrosymmetric crystal structure. Common piezoelectric materials such as quartz (SiO₂), barium titanate (BaTiO₃) and PZT ceramics (lead zirconate titanate) belong to this category.

Within a non‐centrosymmetric structure the electrical dipoles, that is the centres of charge, do not cancel each other out. Consequently, the entire crystal exhibits a net dipole moment. In their natural state, the electrical dipoles are generally randomly distributed and do not show macroscopic polarisation. However, when the material undergoes a polarisation treatment – for example, heating above the Curie temperature, applying a strong electric field and subsequently cooling – the electrical dipoles arrange themselves along the direction of the applied field, resulting in a permanently polarised material.

Fig. 2 Crystal Structure of Quartz (SiO₂)

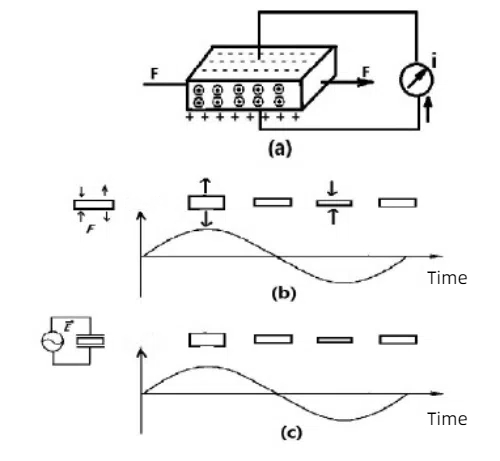

Fundamentals of the Piezoelectric Phenomenon

When a piezoelectric crystal is subjected to mechanical stress (for instance, by compression or tension), small shifts in the electrical dipoles result in a redistribution of charge centres, creating a potential difference that can be measured as a piezoelectric voltage. This process is categorised as the positive piezoelectric effect.

When an electric field is applied to a piezoelectric crystal, the electrical dipoles are rearranged or rotated in response to the field, which produces a mechanical deformation of the crystal. This deformation may lead to movement, as observed in piezoelectric actuators. Such a process is known as the inverse piezoelectric effect.

Fig. 3 Piezoelectric Effect

This effect is principally produced by the rearrangement of electrical dipoles and the coupling between voltage and the electric field. The rearrangement occurs primarily when the material is above its Curie temperature, which allows a free rotation of the dipoles. Once an electric field is applied, the dipoles align with the field direction. On cooling, the alignment is fixed, and the material displays macroscopic polarisation. The coupling between voltage and the electric field is evident as mechanical stress alters the crystal structure slightly, thereby shifting the relative positions of the electrical dipoles and producing measurable charges; similarly, when an electric field is applied, the reorganisation of dipoles causes mechanical strain.

Polarisation of Piezoelectric Crystals

What is Polarisation?

During the polarisation of piezoelectric crystals, the electrical dipoles within the material are aligned in a specific direction by the application of a strong electric field. This treatment is necessary in order for the material to exhibit the piezoelectric effect and to achieve its maximum piezoelectric performance.

Fig. 4 Ceramic Polarisation

Steps in the Polarisation Process

1. Material Preparation: Piezoelectric materials (for example, barium titanate, PZT ceramics, etc.) are processed into the desired shape and size.

2. Heating: The material is heated above its Curie temperature. The Curie temperature is the point at which the material transitions from a ferroelectric phase to a paraelectric phase. At this temperature the electrical dipoles are randomly oriented.

3. Application of an Electric Field: A strong electric field (typically several thousand volts per millimetre) is applied at the elevated temperature. This causes the electrical dipoles within the material to reorient in the direction of the field.

4. Cooling: While the electric field is still applied, the material is cooled below its Curie temperature. During cooling, the alignment of the dipoles is fixed, resulting in a permanently polarised state.

5. Removal of the Electric Field: Once the material has reached room temperature, the electric field may be removed, leaving the material with permanent piezoelectric properties.

Principles of the Polarisation Process

When the material is above its Curie temperature it exists in a paraelectric phase, allowing the dipoles to freely reorient. At this stage, a sufficiently strong electric field is applied so that the dipoles align along the field direction, forming a uniform polarisation. Once the desired alignment is achieved, the temperature is reduced, which fixes the dipole orientation and maintains the polarisation even in the absence of an external electric field.

Importance of the Polarisation Process

Polarisation treatment is critical for the performance of piezoelectric materials. Unpolarised materials do not exhibit measurable piezoelectric effects, whereas polarised materials show significantly improved coefficients, enabling efficient conversion between mechanical and electrical energies. This process is essential for achieving the necessary performance in sensors, actuators and various electronic components.

Common Piezoelectric Materials and Their Applications

1. Quartz

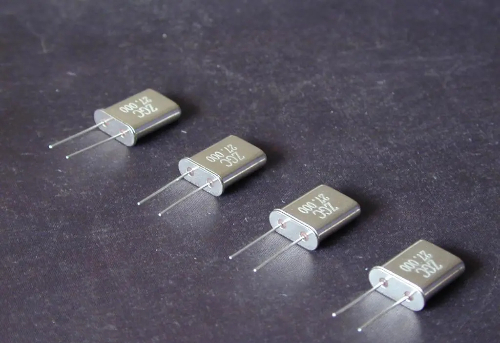

Quartz is a widespread naturally occurring piezoelectric crystal. Its chemical composition comprises silicon dioxide (SiO₂) in a hexagonal crystal system, and it is generally colourless and transparent. With a thermal expansion coefficient of approximately 0.5×10-6/°C and a quality factor of roughly 115 000, quartz performs reliably in high-frequency oscillators and filters despite its relatively low piezoelectric coefficients. Its chemical and mechanical stability, along with sustained piezoelectric performance over a broad temperature range, make it suitable for many technical applications.

Quartz crystals are obtained either by natural extraction or by synthetic production. Natural quartz is relatively simple and cost-effective to source, while synthetic quartz is often used when high purity and specific dimensions are required. The slicing and processing of quartz can be precisely controlled to ensure optimal performance. Different cut orientations, such as AT-cut and BT-cut, affect the measured piezoelectric properties.

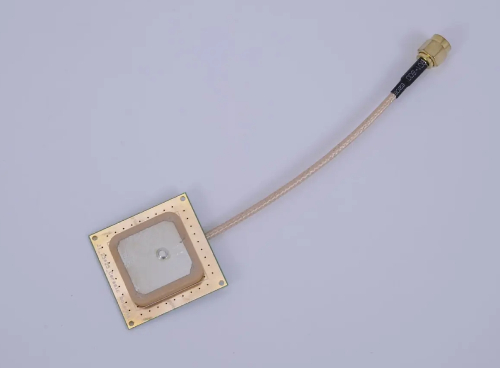

Quartz crystal oscillators are employed in electronic devices such as wristwatches, computers and mobile telephones to provide accurate time references. Quartz-based filters are used in wireless communication devices to ensure stable signal transmission. Furthermore, quartz is used in pressure sensors, accelerometers and microphones to transform mechanical vibrations into electrical signals in industrial automation, aerospace and audio equipment. In addition, quartz is utilised in devices with surface acoustic waves (SAW), including SAW filters and sensors for signal processing and environmental monitoring. Optical components such as modulators, prisms and lenses are fabricated using quartz crystals. In ultrasonic equipment, quartz-based transducers are applied in medical diagnostics and industrial testing, while in metrology, quartz serves as a frequency standard in measurement instruments and signal generators. Its demonstrated stability, precision and cost-effectiveness have established quartz as an indispensable material in modern technology and industry.

Fig. 5 Quartz Crystal Filter

2. Barium Titanate

Barium titanate (BaTiO₃) is typically found as colourless or white crystals. Its crystal structure undergoes various phase changes (for example, tetragonal, cubic and hexagonal) depending on temperature. The piezoelectric properties of barium titanate are derived from phase transitions and symmetry changes within its structure as temperature varies. Barium titanate maintains its piezoelectric characteristics across an extended temperature range and is thus appropriate for use under varied conditions.

The piezoelectric constants for barium titanate are quantified, with d31 around –80×10-12 C/N and d33 approximately 190×10-12 C/N. Its dielectric constant at room temperature is about 1 200, which yields a high capacity in capacitor applications.

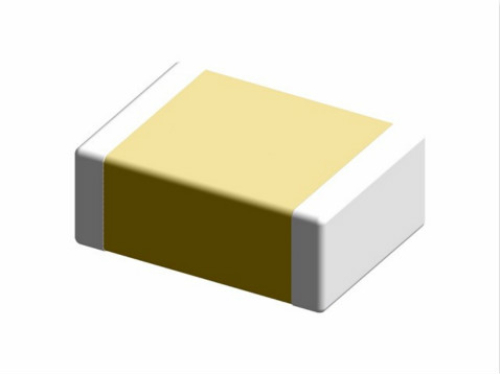

In electronic devices, barium titanate is used to fabricate multilayer ceramic capacitors (MLCCs), which combine high capacitance with small dimensions, and are common in smartphones, computers and domestic appliances. Its use in sensor technology includes pressure and acceleration sensors employed in industrial automation, medical instrumentation and automotive electronics.

Barium titanate is further utilised in piezoelectric actuators that produce mechanical deformation when voltage is applied. These actuators find application in precision positioning systems, microelectromechanical systems (MEMS) and optical adjustment equipment. In addition, barium titanate is implemented in piezoelectric filters and resonators incorporated within wireless communications to maintain signal clarity and transmission quality. Its piezoelectric attributes are also exploited in energy harvesting devices that convert ambient mechanical vibrations into electrical energy for operating low-power devices.

Fig. 6 Ceramic Multilayer Capacitors

3. Lead Zirconate Titanate (PZT)

Lead zirconate titanate (PZT) is an extensively used piezoelectric ceramic material. Its chemical formula is Pb(ZrₓTi₁₋ₓ)O₃ and its structure varies with the Zr/Ti ratio, including transitions between tetragonal and cubic phases. The phase transitions occurring at different temperatures influence its piezoelectric performance.

In ultrasonic devices, PZT is employed to produce transducers for medical diagnostics, industrial testing and underwater sonar systems. In sensor applications, the piezoelectric effect of PZT is used to manufacture pressure and acceleration sensors for industrial automation, medical devices, vehicle safety systems and earthquake monitoring.

Piezoelectric actuators made of PZT convert electrical energy into mechanical deformation, which is applied in precision positioning, optical adjustment and fine movement control in pressure instruments and microscopes. In addition, PZT materials are used in piezoelectric filters and resonators in wireless communication systems to ensure proper frequency selection and control. Energy harvesting applications also utilise PZT to convert mechanical or vibrational energy into electrical energy for powering wireless sensor networks and portable devices. PZT is additionally found in acoustic devices such as loudspeakers and microphones that convert electrical signals into sound waves or vice versa.

Fig. 7 Piezoelectric Lead Zirconate Titanate Ceramic Plate

4. Zinc Oxide (ZnO)

Zinc oxide crystallises in a hexagonal wurtzite structure. This non‐centrosymmetric arrangement of Zn²⁺ and O²⁻ ions produces an electric dipole moment under applied voltage, thereby exhibiting a piezoelectric effect. The material is known to have a high piezoelectric constant and a satisfactory electromechanical coupling coefficient.

Due to these properties, ZnO is used in sensors such as gas and pressure sensors that are applied in industrial automation and consumer electronics. In actuator applications, zinc oxide is used in microelectromechanical systems (MEMS) and in acoustic devices that require precise positioning and audio output. The piezoelectric characteristics of ZnO are also applied in energy harvesting, for example, in nanogenerators and piezoelectric energy collectors that convert mechanical energy into electrical energy for low-power devices.

ZnO is furthermore employed as a transparent electrode material in optoelectronic devices, including LEDs and photodetectors, in order to improve photoelectric conversion efficiency. Zinc oxide nanomaterials are used in biosensors for detecting biomolecular and cellular activities, particularly in medical diagnostics and biological research. Its quantifiable electrical and chemical properties ensure its application in modern electronic, communication, medical and industrial automation systems.

Fig. 8 Zinc Oxide Varistors

5. Lithium Niobate (LiNbO₃)

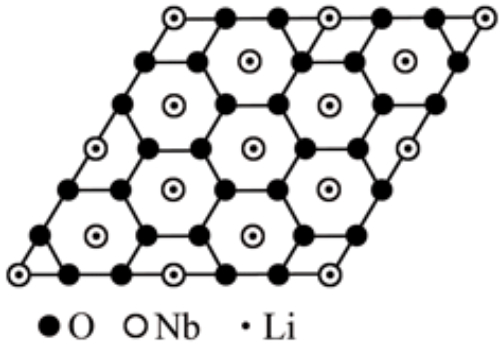

Lithium niobate (LiNbO₃) is an important piezoelectric crystal owing to its significant piezoelectric, electro-optic, nonlinear optical and acousto-optic properties. It has a tetragonal crystal system with a wurtzite-related structure. The non‐centrosymmetric nature of the structure produces piezoelectric and electro-optic effects, as the displacement of lithium and niobium ions under an electric field shifts the positive and negative charge centres.

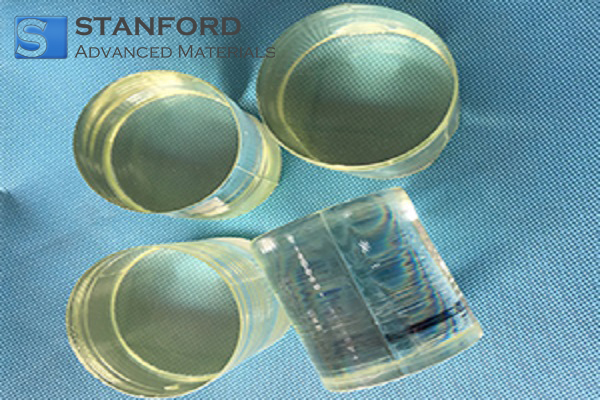

Lithium niobate is reported to have high piezoelectric constants and a high electromechanical coupling coefficient, making it suitable for a range of applications. As a piezoelectric crystal, LiNbO₃ finds use in the fabrication of electro-optic modulators and waveguides for optical communication and integrated optics. In acousto-optic devices, it is used in modulators and delay lines for the modulation and processing of light beams and radiofrequency signals.

In sensing applications, accelerometers and pressure sensors made of lithium niobate are used in aerospace, automotive safety systems, and earthquake monitoring as well as in industrial automation. Piezoelectric filters and resonators from LiNbO₃ are implemented in wireless communication systems to select and control frequencies, thereby ensuring signal quality. In laser systems, the nonlinear optical properties of lithium niobate are exploited in frequency multipliers and optical parametric oscillators to enable laser frequency modulation and wavelength adjustment. Furthermore, LiNbO₃ is applied in medical ultrasound devices and biosensors which facilitate precise ultrasonographic imaging and biomolecule detection.

Fig. 9 Crystal Structure of Lithium Niobate

6. Lithium Tantalate (LiTaO₃)

Lithium tantalite (LiTaO₃) is a piezoelectric crystal with significant piezoelectric, electro-optic, acousto-optic and nonlinear optical characteristics. It has a calcite structure with a three-part crystal system. Its non‐centrosymmetric structure imparts piezoelectric, electro-optic and nonlinear optical properties, allowing for effective conversion of mechanical energy into electrical energy and vice versa.

As a piezoelectric crystal, LiTaO₃ is used in the production of electro-optic modulators and optical waveguides for optical communication and integrated optics. In acousto-optic devices, lithium tantalite is applied in modulators and delay lines, which are used for the modulation and processing of light beams and high-frequency signals.

In sensor technology, devices such as accelerometers and pressure sensors based on lithium tantalite are employed in aerospace, vehicle safety systems, earthquake monitoring and industrial automation. Piezoelectric filters and resonators made from LiTaO₃ are used in wireless communications to select and control frequencies, thereby ensuring signal quality.

Nonlinear optical properties of lithium tantalite are utilised in laser applications for manufacturing frequency multipliers and optical parametric oscillators, which assist in laser frequency modulation and wavelength adjustment. In addition, its use is noted in medical ultrasound devices and biosensors, which enable precise ultrasound imaging and biomolecular detection. The quantifiable piezoelectric performance, measurable electro-optic effect and stable chemical structure render lithium tantalite a valuable material in applications spanning electronics, communications, optics, medicine and industrial automation.

Fig. 10 Lithium Tantalate Crystal

Conclusion

Piezoelectric crystals are capable of converting mechanical energy into electrical energy and vice versa owing to their microstructural characteristics. The study and application of piezoelectric crystals such as quartz, lithium niobate and lithium tantalite have significantly influenced modern scientific and technological development, while simultaneously demonstrating the potential of material science to address practical challenges.

Given the increasing demand for materials with specific properties, further advances in piezoelectric crystal technology are expected to extend the limits of current technology and contribute to increased innovation and progress in society. Stanford Advanced Materials (SAM) is positioned at the forefront of supplying high-quality piezoelectric materials to meet this growing technological need.

References:

[1] Nogueira A E F, Campos B V R, Nascimento D C P J, et al. Piezoelectric temperature acoustic sensor of LiNbO₃ crystal fibers operating at radio frequencies [J]. Journal of Crystal Growth, 2024, 643 127799–127799.

Further Reading:

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento