How Is Molybdenum Extracted

Methods for the Processing of Molybdenum Ore

The primary method for processing molybdenum ore is flotation.

The molybdenum mineral obtained by flotation is molybdenite. Non‐polar oils are used as collectors and a frother is added. To ensure the quality of the molybdenum concentrates, copper, lead, iron and other metal minerals as well as calcium oxide and carbonaceous minerals must be separated from the molybdenum concentrate. Sodium sulphide and cyanide may be applied to prevent the precipitation of iron and copper impurities.

Smelting Process of Molybdenum Concentrates

In the smelting of molybdenum concentrate, the following methods are applied:

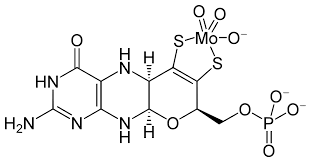

Oxidation Roasting: Molybdenite is roasted by calcination. It is followed by a sublimation or a wet process in order to produce ammonium molybdate–molybdenum trioxide. Ammonia is added to the solution to separate the insoluble compounds. The ammonium molybdate crystals are recovered by concentration and crystallisation or an acid precipitation is employed to form a molybdate precipitate, thereby separating the soluble impurities. After calcination, pure molybdenum trioxide is produced and is then processed by hydrogen reduction to yield metallic molybdenum. Depending on the design of the roasting installation or the different added components, the process is divided into rotary kiln, shaft furnace, fluidised bed and re-calcining oven roasting. This method generates a substantial volume of smoke, pollutes the environment and yields a low recovery rate of molybdenum; nearly all of the rare element rhenium is lost with the smoke gas. Consequently, it is not suitable for processing low-grade or complex ores.

Nitric Acid Leaching: In this method, MOS2 is oxidised to produce soluble molybdate in an autoclave. Cost-effective oxidising agents – air or pure oxygen – are used. This method requires high temperatures and high pressures, thereby imposing strict demands on the reaction equipment and conditions. The process is difficult to control and entails certain safety risks. Consequently, its application has been suspended.

Sodium Hypochlorite Leaching: This method is primarily used for leaching low-grade ore wastes. During the leaching process, sodium hypochlorite gradually releases oxygen. Some metal sulphides are oxidised by sodium hypochlorite–hydroxide ions, causing these metals to precipitate and thereby promoting the formation of molybdate, while the molybdenum solution is converted to slag. The process requires mild reaction conditions and simple production control with minimal equipment demands; however, the consumption of sodium hypochlorite is high and the production costs are elevated.

Electro-oxidation Leaching Method: This method represents an improvement on the sodium hypochlorite technique. A molybdenite mineral slurry is added to an electrolytic tank containing a sodium chloride solution. In the electro-oxidation process, chlorine (Cl2) and the products at the anode react with water to generate hypochlorite. The hypochlorite oxidises the molybdenum sulphide in the mineral to produce molybdate in solution. The method delivers a high leaching efficiency, operates under mild reaction conditions and avoids environmental pollution. Reaction direction, limit and rate can be conveniently controlled.

New methods have recently been developed. For example, unroasted molybdenite is directly processed using an oxygen pressure cooking method or bacterial leaching is applied to extract pure molybdenum trioxide. For low-grade oxide ores, sulphuric acid is used for leaching; ion exchange and extraction processes are employed to obtain pure molybdenum trioxide from the solution.

Overview of the Applications of Molybdenum

Molybdenum is primarily used in the iron and steel industry, which accounts for approximately 80% of total molybdenum consumption. The chemical industry follows with about 10%. Additionally, molybdenum is applied in the electrical and electronics industries, in medicine, in agriculture and in other sectors, which together account for approximately 10% of overall consumption.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento