The Era Of Graphene: Unleashing A Revolution In Material Science

Within the evolving field of materials science, a new material is repeatedly identified that may significantly alter technology and industry. Graphene is one example that has been studied for its physical properties. Its applications include increasing computational speed and improving the performance of medical implants, thereby potentially supporting measurable technological progress.

The potential of graphene

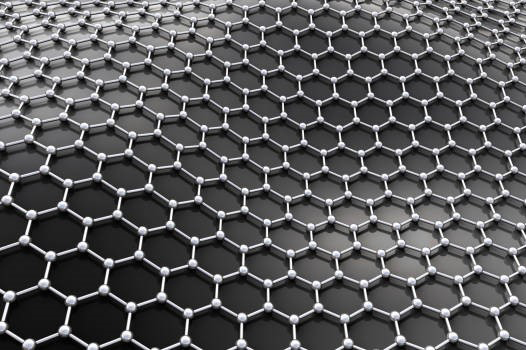

Graphene comprises a single layer of carbon atoms arranged in a hexagonal lattice. This structure yields measurable properties such as high tensile strength, flexibility, and electrical conductivity. Its properties were first studied theoretically in the 1940s. Andre Geim and Konstantin Novoselov were awarded the Nobel Prize for Physics in 2010. A micro-mechanical cleavage technique using adhesive tape was developed to isolate graphene layers, thereby increasing availability for experimental study.

Graphene in industry

Graphene may impact various industrial sectors. In the computer industry, graphene in combination with boron nitride may be used to develop transistors that reduce response times and overcome miniaturisation limits imposed by Moore’s Law. Its electron band structure differs from that of conventional semiconductors, thereby facilitating the development of more efficient solar cells. The measured strength and flexibility of graphene support progress in construction and manufacturing. This may lead to the production of structures and vehicles that are stronger, lighter and more durable. Graphene’s transparency and conductivity allow its use in developing responsive, flexible touchscreens that may improve digital device performance.

Medical and environmental applications

In medicine, the mechanical properties of graphene may be utilised to develop new prostheses and implants that fulfil performance requirements while reducing weight. In addition, using graphene in personal protective equipment may increase durability without adding significant weight, thereby meeting occupational safety standards.

Challenges and future prospects

Widespread adoption of graphene depends on the ability to manufacture it at scale and at moderate cost. Developing cost-effective and efficient production methods remains a key challenge. Ongoing improvements in production techniques and increased understanding of graphene properties render its integration into everyday technology and industrial applications increasingly feasible. Research on graphene extends into fields such as high-energy physics and cosmology. Its properties may contribute to quantitative findings in quantum mechanics and other scientific areas. Current studies have not yet fully characterised graphene’s potential. Continuing research and advancements in production methods may soon alter the technological framework and introduce new material applications in the twenty-first century.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento