The Processing Of Titanium Clad Copper Parts

The Processing of Titanium-Clad Copper Components

1. Our process mainly comprises explosion plating and rolling.

Explosion Plating

2) Explosion plating is a method that uses the energy produced by an explosive detonation to join sheets.

Manufacturing of Explosion Platings

3. The manufacturing of explosion platings:

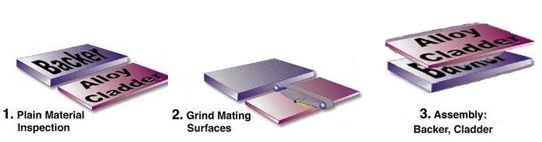

a. Pre-clad: Evaluation of the pure material → Surface grinding → Assembly (Backer & Cladder)

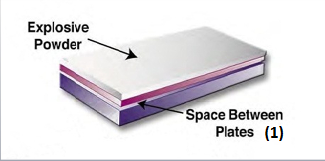

b. Pre-clad assembly

Encasing and base metal plates are arranged parallel with a prescribed gap. The explosive charge is positioned on top.

c. Encapsulation:

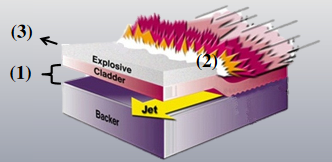

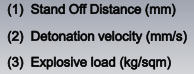

The detonation propagates over the plate at approximately 2 000 m/s (2 & 3);

The essential variables are:

d. Post-clad:

Flattening and cutting → Inspection (ultrasonic testing)

4. Rolling

5. Straightening → Machining → Polishing

Conclusion

We thank you for reading our article and trust it will assist in understanding the processing of titanium-clad copper components. If you require further information on titanium-clad copper components and other high-melting-point metals and alloys, please visit Stanford Advanced Materials (SAM) to obtain further information.

Stanford Advanced Materials (SAM) is a global supplier of titanium products and has over two decades of experience in the manufacture and distribution of titanium products. The company supplies titanium and titanium-clad copper components to meet the R&D and production requirements of its clients. Accordingly, we are confident that SAM will serve as your preferred supplier and business partner for titanium-clad copper components.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento