Direct Energy Disposition - 3D Printing Methods

Direct Energy Disposition (DED) is one of the additive manufacturing processes. Additive manufacturing (AM) may not be entirely familiar to all. It is also known as 3D printing, Rapid Prototyping (RP), layer manufacturing, etc. The core principle of additive manufacturing is the utilisation of 3D model data to join materials layer by layer. Without the requirement for tools or pre-manufactured moulds, AM exceeds traditional manufacturing methods and is currently one of the most widely employed techniques. As various materials such as plastics, metals, ceramics, composites and biological substances can be used as feedstock, many industries have begun to adopt this technology or already use it. AM permits the production of complex and specific designs.

Additive manufacturing comprises four techniques: binder jetting, powder bed fusion, sheet lamination and direct energy deposition (DED). As indicated by the title, this article focuses on direct energy deposition.

What is direct energy deposition?

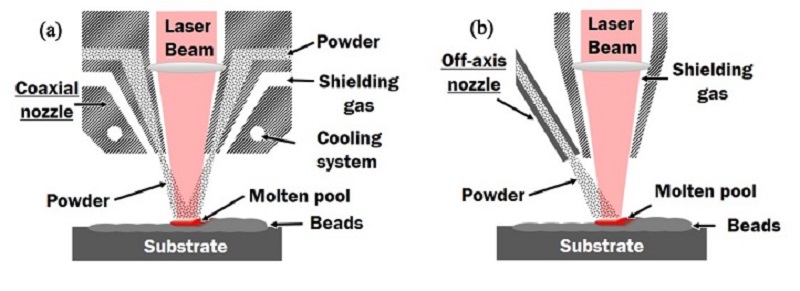

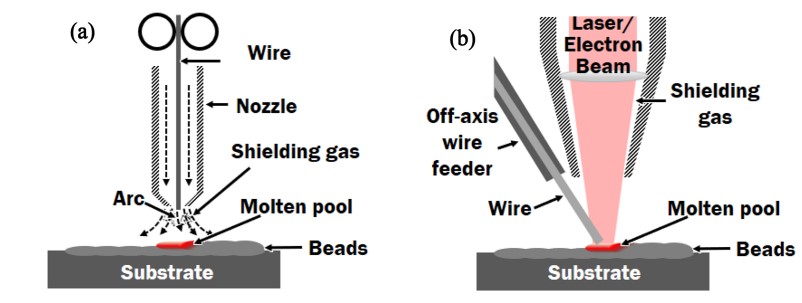

In direct energy deposition, thermal energy in the form of a laser, an electron beam or another energy source is utilised to melt the material and fuse the deposited material with new feedstock. It combines coating and welding processes. DED utilises not only powders, as the other four AM methods do, but also wires as a feedstock. Depending on the type of feedstock, DED can be divided into powder and wire processes. In the powder-feed DED process, a laser serves as the heat source to melt both the powder and the preceding layers. In the wire-feed process, a laser, an electron beam or a plasma arc may be employed as the heat source. The following Figures 1 and 2 provide a brief overview of these two distinct DED technologies.

Figure 1: DED with powder feeding: (a) coaxial feeding; (b) off-axis feeding [1]

Figure 2: DED with wire feeding: (a) coaxial feeding; (b) off-axis feeding [1]

DED can be categorised by the feed location into coaxial and non-coaxial feeding. Shielding gas is used to protect the material, especially active metals, from oxidation due to high temperatures.

The principal working principle is as follows:

* The nozzle deposits the feedstock (powder or wire) onto the substrate.

* A heat source (e.g. a laser) melts a specific area and fuses the material to form a layer.

The nozzle and the laser beam then move continuously to other areas, thereby repeating the process under computer control. Direct energy deposition is performed in a line-by-line manner and can be applied on non-horizontal planes.

Difference between DED with powder feed and DED with wire feed

The DED process with wire feed attains a higher deposition rate and produces thicker layers compared with the powder-feed process. However, the powder-feed DED method is more precise and exhibits lower residual stresses. These differences mean that each technique is frequently applied to different applications.

The powder-feed DED process is often employed in restoration, porous coatings, custom-designed materials, customised structures and heat management. Unlike powder bed fusion or binder jetting, DED can be applied in restoration because it is capable of operating on non-horizontal planes.

The wire-feed DED process is frequently used for the production of large components, for instance turbine blades.

Application of direct energy deposition in restoration

This method is applied for the repair and restoration of components, particularly in cases where full replacement is time-consuming and expensive. For example, if a section of an integrally bladed rotor in modern turbine engines is damaged, it is less cost-effective to replace it with a new blade than to restore it. General technologies are not easily applied in such cases. DED addresses this issue with relatively low heat input, minimal distortion, adequate metallurgical bonding and precise applicability.

Powder-feed DED demonstrates enhanced restoration performance relative to wire-feed DED. However, neither process can fully restore the fatigue properties, yield strength or ductility of the original component, due to porosity, contamination or other factors.

Continued development of DED technology will likely increase the size and complexity of components that can be produced with this process. Consequently, manufacturers and restoration operations will gain new prospects, which may contribute to the development of entirely new products and sectors.

Summary

Direct energy deposition is a precise and exact manufacturing process that has the potential to fundamentally change the methods used in the production and repair of components. Although it is currently limited to the production of small parts, ongoing technological developments are expected to expand its capabilities in the future. The high costs of the equipment required for DED may pose an obstacle for some companies, although the advantages of the process render it an increasingly favoured choice for a broad range of applications.

Reference

- Ahn, DG. Gerichtete Energieabscheidung (DED) Prozess: State of the Art, Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 703-742 (2021). https://doi.org/10.1007/s40684-020-00302-7

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento