Survey Of High Field Superconducting Materials For Accelerator Magnets

Introduction

High‐energy particle accelerators are critical to modern scientific research. They support investigations in particle physics, materials science and medical diagnostics. The performance of these accelerators depends on superconducting magnets that produce strong magnetic fields to guide and focus charged particles. This article examines superconducting high‐field materials deployed in accelerator magnets and explains their role in advancing scientific research.

The Requirement for High‐Field Superconductors

Accelerators such as synchrotrons, cyclotrons and linear accelerators are essential tools in fundamental research across particle physics, materials science and medical applications. These devices require strong magnetic fields to guide and focus charged particles efficiently. Superconducting materials, which exhibit zero electrical resistance and carry high current densities without energy losses, are necessary to produce the required fields.

Historical Overview

The development of superconducting high‐field materials for accelerator magnets began after the discovery of superconductivity in 1911. Initially, low‐temperature superconductors such as Niobium‐Titanium (NbTi) and Niobium‐Tin (Nb3Sn) were used. These materials improved accelerator performance; however, they present limits regarding magnetic field strength and cooling requirements.

Advanced High‐Field Superconductors

In recent decades, researchers have investigated high‐temperature superconductors (HTS) as alternatives. Yttrium‐Barium‐Copper‐Oxide (YBCO) and Bismuth‐Strontium‐Calcium‐Copper‐Oxide (BSCCO) have been studied. They operate at higher temperatures than low‐temperature superconductors, thereby offering practical advantages for specific applications.

Key Properties and Advantages

High critical magnetic field (Hc): High‐field superconductors withstand stronger magnetic fields. This capacity permits the design of accelerator magnets that are both compact and efficient.

High critical current density (Jc): These materials carry high current densities. This results in magnet constructions that operate with improved current handling.

Operational efficiency: The absence of electrical resistance reduces energy consumption and cooling requirements.

Compact design: Superconducting high‐field magnets can be physically smaller than conventional magnets, thereby saving space and lowering cost.

Applications in Particle Physics

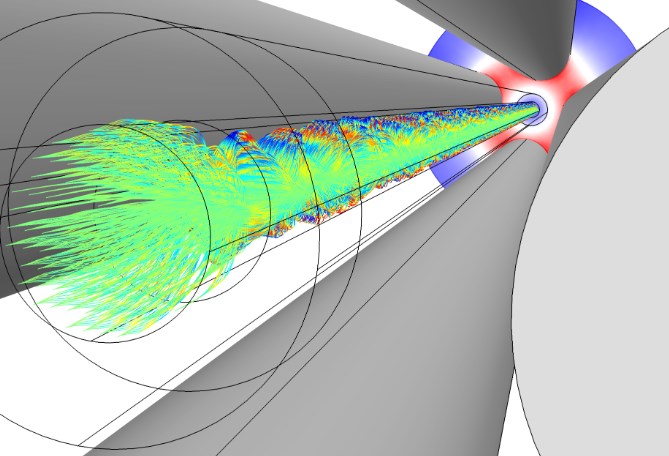

High‐field superconducting materials are used in several experiments and installations in particle physics. The Large Hadron Collider (LHC) at CERN and projects such as the Future Circular Collider (FCC) deploy these materials. They produce magnetic fields that facilitate higher collision energies and precise control of particle trajectories.

Pursuit of Higher Energies

Particle accelerators, including the LHC at CERN, require increasingly strong magnetic fields to achieve higher particle energies. Superconductors provide low electrical resistance when cooled to very low temperatures. Given that future accelerator projects demand magnets with higher field strengths, researchers are focusing on superconducting materials that perform at elevated fields.

Niobium‐Titanium (NbTi): The Pioneer

Niobium‐Titanium superconductors (NbTi) were among the first materials employed in accelerator magnets. They have been used to generate fields of up to approximately 9 Tesla. Their use remains widespread, although performance has reached a limit at about 9 Tesla.

Niobium‐Tin (Nb3Sn): Extending Performance Limits

Researchers turned to Niobium‐Tin superconductors (Nb3Sn) to attain higher magnetic fields. Nb3Sn magnets have been shown to operate at critical fields above 15 Tesla. Despite a complex manufacturing process, these magnets have been used in projects such as the LHC, which require higher field strengths.

High‐Temperature Superconductors (HTS): A Notable Development

The introduction of high‐temperature superconductors (HTS) has altered magnet design for accelerators. Materials based on Yttrium‐Barium‐Copper‐Oxide (YBCO) or Bismuth‐Strontium‐Calcium‐Copper‐Oxide (BSCCO) operate at higher temperatures than traditional superconductors. HTS systems have demonstrated critical fields exceeding 30 Tesla and offer improved performance for future accelerator applications.

Challenges and Future Prospects

High‐temperature superconductors face challenges associated with production and cooling systems. Researchers are addressing these issues in order to fully utilise HTS in accelerator magnets. In addition, investigations into new superconducting materials such as Magnesium Diboride (MgB2) and iron‐based superconductors may yield further improvements in high‐field applications.

Conclusion

This review of superconducting high‐field materials for accelerator magnets illustrates an evolution in accelerator technology. From the early adoption of NbTi to the adoption of HTS materials, research into higher energies and stronger magnetic fields continues. Researchers and engineers extend the limits of superconductivity to meet the performance demands of future accelerators.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento