What Is Binder Jetting 3D Printing?

What is 3D Printing?

3D Printing, also known as additive manufacturing (AM), is a novel alternative method for the fabrication of components or products by the sequential deposition of materials. In 3D printing, materials are added rather than removed to create shapes or network structures. This method enables the production of complex, customised and otherwise unachievable components when compared with traditional manufacturing. Since 2014, numerous research studies and articles have been published on this subject[1]. It is now being implemented across a wide range of industries, thereby questioning conventional technologies.

3D printing can be categorised into two groups. The first employs fusion‐based methods such as Powder Bed Fusion (PBF) and Directed Energy Deposition (DED); the second utilises non-fusion-based methods such as Binder Jetting (BJ). This article focuses on binder jetting technology.

What is Binder Jetting?

Binder Jetting (BJ) is one of the most frequently employed 3D printing technologies. In this process, the powder is spread in a layer on the powder bed and selectively bound using a binder, typically a polymer liquid. The three-dimensional geometry is formed by the successive binding in the powder container. When the unbound powder is removed, the printed “green” parts remain. These green parts require post-processing, for example by sintering and impregnation, to achieve the required properties for use.

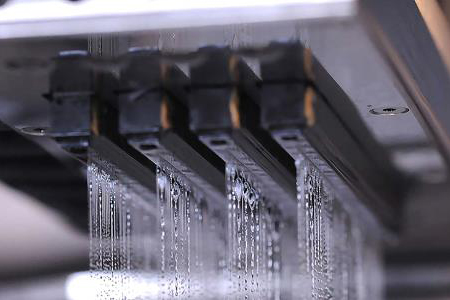

Improvements in the sintering process for small parts and lattice structures have led to the extensive application of binder jetting in electrochemical energy storage, electronic devices, food technology, solid oxide fuel cells [66], in patterns for sand casting [67–76], in hollow conductive circuits and antennas, in concrete construction, with renewable bio-based materials, in ceramic scaffolds, biopolymers, sandstone manufacture, as well as in biomedical applications and drug delivery. Figure 1[1] shows the print head for a binder jetting printer.

Detailed Process of Binder Jetting

For all additive manufacturing processes, a designed or scanned CAD model is the key element for creating thin-layer data for printing. The thin layer is then spread onto the powder bed, usually by means of a counter-rotating roller. Computer-controlled, the print head deposits the binder (polymer) in accordance with the CAD model onto the layer. The binder saturation should be calculated based on the powder density and input by the operator. Figure 2 illustrates the structure of a binder jetting machine for reference.

After the binder is applied, it is heated by an electrical heater so that the subsequent layer can be deposited. The maintenance of a constant temperature contributes to the quality of each individual layer. The curing or drying of the binder is essential to prevent cracks in the powder bed or the adhesion of powder to the roller. The piston then descends by one layer, typically 50 to 200 µm, thereby creating a new powder layer which is spread by the roller. These steps are repeated until the “green” part is produced.

Post-Processing of Binder Jetting

After printing, a post-curing step is sometimes necessary to achieve adequate strength in the “green” part. The entire powder container is placed in an oven at 180 to 200 °C for several hours, depending on the quantity and quality of the binder. Afterwards, the “green” part is removed from the powder bed, a process known as depowdering. A brush or vacuum system may be used to remove the loose powder. Caution is required during this process, as the green part is relatively porous and held together by the binder. Another method for drying or curing employs light, whereby the green part can be removed directly from the machine.

After drying, the polymeric binder is removed by heating to approximately 600 to 700 °C. The next step is sintering or infiltration. Sintering is commonly used for metal powders as the sintering temperature is lower compared with that for ceramic powders. Sintering parameters are complex. For powders of different materials and varying particle sizes, the sintering temperature, atmosphere and hold time differ. The sintering parameters should be chosen according to the material tolerance and the dimensions of the final product. Infiltration generally results in more precise properties than sintering, which may lead to geometric distortions. [4]

The final step is the polishing of the consolidated part to reduce the surface roughness.

Advantages and Disadvantages of Binder Jetting

Advantages:

- In binder jetting, the powder is neither fused nor sintered. There is no concern regarding the oxidation of the powder. Expensive sealed chambers to achieve a vacuum or inert atmosphere are unnecessary.

- The entire process is conducted at room temperature, so the final product does not exhibit residual stresses.

- Process speeds are higher than those of other additive manufacturing methods.

- Binder jetting facilitates the use of various types of powders.

Disadvantages:

- The post-processing procedure is relatively complex.

- The surface of the produced parts is rougher than that produced by other AM processes.

- Different materials necessitate different post-processing parameters.

Powder Material Used in Binder Jetting

Binder jetting utilises powder materials ranging from 0.2 to 200 µm as raw material. Reports indicate that 20 µm represents a turning point, as powders larger than 20 µm are considered coarse. Theoretically, the finer the powder, the higher the resolution of the product produced using binder jetting. However, fine powder is more difficult to distribute uniformly in each layer owing to reduced flowability.

Spherical powders such as metals, sand and ceramics are commonly used for binder jetting. With spherical powders, a homogeneous microstructure is achievable, thereby preventing the formation of macro-pores through which the binder might not penetrate. In other words, spherical powders facilitate the production of denser “green” parts than irregular powders. The density is positively correlated with the strength of the part.

Further reading: 3D Printing Powder: What is it and how is it used?

Applications of Binder Jetting

Binder jetting finds diverse application in industry, dentistry, medicine, aerospace, casting parts production, the luxury goods sector and other fields. While binder jetting is mainly applied in structural and functional ceramics, recent performance in biomedical engineering has been noted with the use of hydroxyapatite or tricalcium phosphate powders. Spherical Al2O3 powder, spherical SiO2 powder and Si3N4 powder are the structural and functional powders employed in binder jetting.

For further information, please visit the Stanford Advanced Materials Homepage.

Reference:

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binderjet 3D Printing – Process Parameters, Materials, Properties, Modelling and Challenges (p. 2). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binderjet 3D Printing – Process Parameters, Materials, Properties, Modelling and Challenges (p. 6). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binderjet 3D Printing – Process Parameters, Materials, Properties, Modelling and Challenges (p. 7). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binderjet 3D Printing – Process Parameters, Materials, Properties, Modelling and Challenges (p. 9). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- What is Binder Jetting? ExOne. (n.d.). Retrieved 19/12/2022, from https://www.exone.com/en-US/Resources/case-studies/what-is-binder-jetting

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento