Soaring Cobalt Prices Have Led To The Evolution Of New Battery Technologies

In 1980, John Goodenough invented the first lithium-ion battery in Oxford that used cobalt. Experiments have demonstrated that cobalt has a very high energy density. This property renders it especially suitable for small batteries that require a high level of energy output.

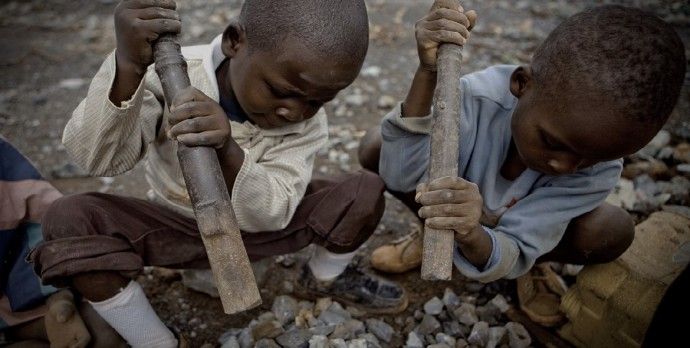

Cobalt is now used in most commercially available lithium-ion batteries. It is expensive; consequently, a problematic profit chain has emerged. In the Republic of the Congo, human rights violations have occurred for many years, including incidents of child labour in mining. Electronics and electric vehicle companies prefer not to incur high manufacturing costs or become involved in local human rights abuses. Consequently, they have reduced the use of cobalt in their batteries. Panasonic, Tesla’s battery supplier, announced at the end of last month that it had developed cobalt-free batteries. Researchers such as Goodenough support this development.

The battery comprises a positive electrode, typically graphite, and a negative electrode that is a mixture of Lithium, Cobalt and oxygen. In an electric vehicle battery, the negative electrode often contains a higher proportion of Nickel than the electronic component, thereby reducing the reliance on cobalt. However, this change has led to higher processing costs and an increased risk of fire in aircraft, as observed with the battery in the Samsung Note 7. By contrast, the electrons in the outer orbital of cobalt atoms are paired. This implies that cobalt is compact, dense and easy to layer.

A new generation of battery researchers, including Goodenough, are now utilising materials such as Manganese and Iron. Unlike layered structures, these elements form a rock salt structure. The negative electrode containing rock salt has already been used in several devices. However, the rock salt structure does not provide the same high energy density as cobalt or nickel.

Researchers are also developing solid-state batteries. These batteries require more lithium but do not necessarily use cobalt and are considerably safer than current lithium-ion batteries. Automobile manufacturers such as BMW, Toyota and Honda are working on these batteries. Olivetti, the energy research expert at MIT, does not believe that the technology will be market-ready by 2025. Until then, companies will attempt to reduce the use of cobalt batteries. Companies such as Apple and Samsung have joined the Responsible Cobalt Initiative, which aims to mitigate environmental pollution and reduce the negative social impacts of cobalt production. Recently, Apple began purchasing cobalt directly from miners to ensure that cobalt suppliers meet the industry’s safety requirements.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento