Essential Electronic Materials: Part 7 - Magnetic Materials

1 Introduction to Magnetic Materials

Magnetic materials are substances that exhibit magnetic properties as a result of their internal structure. They can produce a magnetic field or be affected by an external magnetic field. They attract or repel other materials, and their magnetic behaviour is essential for many modern electronic devices.

Magnetic materials are used in the electronics industry for energy storage, transmission and conversion. They are employed in applications ranging from energy‐efficient devices to modern communication systems. They are used in components such as motors, transformers, sensors, magnetic storage devices and antennas, thereby supporting sectors including electronics, telecommunications, energy, automotive and healthcare.

2 Types of Magnetic Materials Used in Electronics

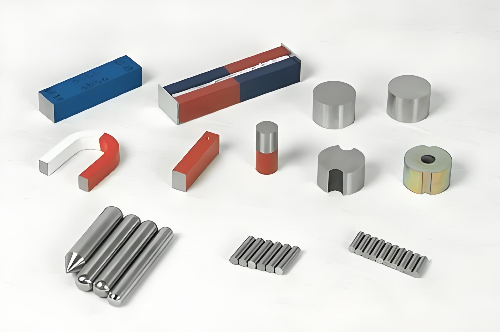

2.1 Hard Magnetic Materials (Permanent Magnets)

Hard magnetic materials, also known as permanent magnets, retain their magnetisation over extended periods. They require a coercivity in the range of Hc = 10^4 to 10^6 A/m. They possess thick hysteresis loops, a high maximum magnetic energy product (BH)max and high remanence.

2.1.1 Alnico Alloys

Alnico alloys are commonly used permanent magnet materials that exhibit high coercivity and remanence. They maintain their magnetic properties after exposure to strong external magnetic fields. They have a Curie temperature of 860 °C and a maximum operating temperature between 525–550 °C, thereby ensuring stable magnetic behaviour in high temperature conditions. They show good corrosion resistance and produce non‐linear demagnetisation curves.

Fig. 1: Magnet made from Alnico alloy

2.1.2 Titanium-Cobalt Alloy

The titanium-cobalt alloy is a frequently used permanent magnet material. It can achieve a magnetic induction between 1.0 and 1.25 T and maintain a magnetic energy product of 2.2×10⁵ erg/cm³ at magnetic field strengths of 8.75–11.94 kA/m. Its hysteresis characteristics lead to minimal energy loss during magnetisation reversal, thereby increasing efficiency in systems with variable loads. The alloy maintains its magnetic properties at higher temperatures and is suitable for motor and generator applications in variable temperature environments. Its chemical composition, including elements such as cobalt and vanadium, provides high magnetic performance and mechanical strength.

Fig. 2: Titanium-Cobalt Alloy

2.1.3 Rare Earth-Cobalt Permanent Magnets

Two types of rare earth-cobalt permanent magnets exist: RCo5 and R2Co17, where R represents rare earth elements such as samarium, praseodymium, cerium and lanthanum. RCo5 magnets have a hexagonal CaCu5 crystal structure, whereas R2Co17 magnets have a trigonal crystal structure. RCo5 exhibits high magnetic anisotropy and R2Co17 offers a high magnetic induction and Curie point, given that elements like iron and copper partly replace cobalt. Cobalt magnets exhibit high coercivity and magnetic energy products. They are produced using powder metallurgy and casting methods and are used in microwave devices, circulators, small motors, micro-relays, magnetic bearings and precision instruments.

Fig. 3: Rare Earth-Cobalt Permanent Magnets

2.2 Soft Magnetic Materials

Soft magnetic materials have a coercivity not greater than 1000 A/m. They reach maximum magnetisation under a low external magnetic field. These materials have low coercivity and high permeability. They are easily magnetised and demagnetised and are used in electrical and electronic devices. Common examples include silicon steel sheets (silicon steel laminations) and various soft magnetic ferrites.

2.2.1 Silicon Steel Soft Magnets

Silicon steel soft magnets offer significant benefits in power electronics. Their high saturation magnetic induction means that under the same magnetic flux conditions, less material is required, thereby reducing material usage. Their high specific resistance reduces eddy current losses, and low hysteresis losses ensure effective performance. They are available in forms such as cold-rolled silicon steel, non-oriented electrical steel and oriented electrical steel, which are used for low-frequency transformers, chokes and other components. They are particularly suitable for low-frequency and high-power applications.

![]()

Fig. 4: Silicon Steel Soft Magnet

2.2.2 Soft Magnetic Ferrite

Soft magnetic ferrite exhibits low saturation flux density, low permeability and a low Curie temperature. It shows limited losses at medium and high frequencies and its cost is low. The lower magnetic parameters restrict its range of applications, and improvements have been pursued since the early 21st century. Its relatively low cost facilitates its use in high-frequency markets.

Fig. 5: Soft Magnetic Ferrite

Soft magnetic materials are widely deployed in electronics. They serve as core materials for transformers, chokes, current and voltage converters, thereby reducing energy losses. They are applied in stator and rotor parts of motors and generators to increase performance under high-frequency conditions. They are also used for electromagnetic shielding to reduce interference in electronic systems. In induction heating applications, they improve heating efficiency in processes such as metal heating, plastic forming and welding. Moreover, they are used in filters and power supplies to enhance system efficiency and in magnetic sensors, passive components, position sensors and switches.

2.3 Magnetic Alloys

Magnetic alloys consist of iron and other metallic elements (e.g. cobalt, nickel, rare earths) that possess defined magnetic properties. They are divided into two categories: soft magnetic alloys and hard magnetic alloys.

Soft magnetic alloys have low hysteresis loss and good permeability, making them suitable for transformers, motors and inductors. Examples include silicon steel and iron-nickel alloys. Hard magnetic alloys exhibit a high magnetic energy product and field strength. They maintain stable magnetic properties and are used primarily for permanent magnets. Examples include neodymium-iron-boron (NdFeB), aluminium-nickel-cobalt (AlNiCo) and cobalt-based alloys. They are employed in applications such as motors, sensors and magnetic resonance imaging systems.

Practical performance is measurable. For instance, neodymium-iron-boron (NdFeB) magnets offer a high magnetic energy product and strong magnetic force. Consequently, they are used in motors, wind turbines and loudspeakers. Alnico alloys are preferred in applications that require temperature stability given that they maintain their magnetic properties in high-temperature environments.

Fig. 6: Neodymium-Iron-Boron Magnets (NdFeB)

3 Properties of Magnetic Materials for Electronics

3.1 Magnetic Permeability

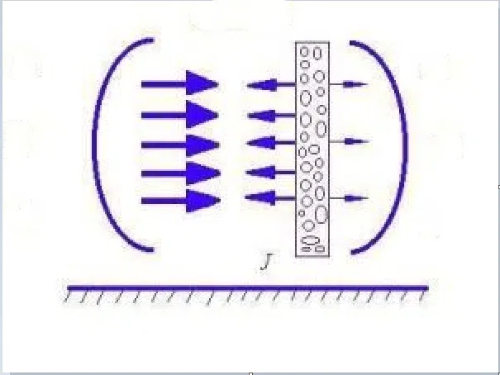

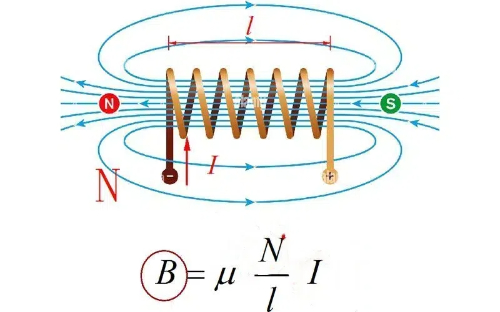

Magnetic permeability is a physical quantity that characterises a material’s response to magnetic fields. It indicates the ability to conduct magnetic field lines when an electric current passes through a coil surrounding the material. The formula is expressed as μ = B / H, where H is the magnetic field strength and B is the magnetic induction. The symbol μ represents the absolute permeability of the medium.

In electronic products, magnetic permeability is important for electromagnetic induction, inductance, magnetic flux closure and electromagnetic shielding. In coils, high permeability improves the induced current relative to the magnetic field strength, thereby enhancing device performance. In magnetic shielding, higher permeability reduces flux dispersion, thereby increasing effectiveness.

Materials with high permeability absorb, reflect or scatter electromagnetic energy, thereby reducing interference in electronic, communications and aerospace devices.

Fig. 7: Magnetic Permeability

3.2 Saturation Magnetic Flux Density

Saturation magnetic flux density (SMFD) is the limit of magnetic induction a material can sustain. When the magnetic field strength increases beyond a certain point, the induction does not rise further. This limit represents the maximum magnetic field that a material can store. The magnitude of SMFD directly affects the maximum magnetic energy stored, thereby influencing component performance.

A higher SMFD means that more magnetic energy can be stored in a given volume, thereby enabling miniaturisation. In transformers, using materials with high SMFD reduces core size and weight while maintaining performance. In high-frequency and high-power applications, selecting materials with high SMFD improves system performance. Note that SMFD decreases with increasing temperature.

Fig. 8: Saturation Magnetic Flux Density

3.3 Coercivity

Coercivity is an important property of magnetic materials. It is defined as the minimum external magnetic field required to reverse a material’s magnetisation. It indicates the material’s ability to resist demagnetisation. High coercivity ensures that the material retains its magnetic properties even under adverse conditions. This is critical for the performance of permanent magnets in applications such as motors, generators and sensors.

Higher coercivity allows a stronger magnetic field to be generated from a smaller volume, thereby supporting applications in miniature devices and precision instruments.

4 Magnetic Materials in Electronic Devices

Magnetic materials are essential components in many electronic devices such as power supplies, transformers, data storage systems, motors, sensors and wireless communication devices. They interact with magnetic fields to facilitate energy conversion, data storage and signal transmission.

4.1 Power Supplies and Transformers

In power supplies and transformers, magnetic materials are used to regulate voltage levels. Transformers utilise soft magnetic cores such as silicon steel or ferrite. Their magnetic properties improve electromagnetic induction, thereby allowing voltage conversion for safe use in households and industry.

4.2 Data Storage

Magnetic materials are fundamental to data storage in hard disk drives and magnetic tapes. In hard drives, thin layers of magnetic material store digital information. Read/write heads alter the magnetic orientation on the disc surface, thereby writing or retrieving data. Magnetic tapes employ similar principles for long-term data retention.

4.3 Motors and Sensors

In motors and sensors, magnetic materials facilitate the conversion of electrical energy to mechanical motion and vice versa. Permanent magnets and electromagnets are used in the construction of motors, including brushless types. Sensors detect the magnetic fields generated by electrical currents, thereby providing essential feedback in control systems.

Fig. 9: Magnetic Sensors

Magnetic materials are also used in wireless communication systems. Components such as antennas, modulators, demodulators and high-frequency elements rely on magnetic materials. They assist in the confinement and direction of electromagnetic waves, thereby improving signal transmission and reception.

5 Conclusion

Magnetic materials are indispensable in a range of electronic devices. They play a key role in energy conversion, data storage, motion control and signal transmission. In power supplies and transformers, they enable efficient voltage regulation. In data storage systems, they allow reliable data recording and retrieval. In motors and sensors, they facilitate proper energy conversion and precise measurement. Additionally, magnetic components in wireless devices enhance the performance of antennas and high-frequency components. Overall, magnetic materials constitute the foundation for modern electronics.

Stanford Advanced Materials (SAM) provides high-quality magnetic materials and supports critical applications with reliable material solutions.

Further Reading:

Essential Electronic Materials: Part 1 - Silicon

Essential Electronic Materials: Part 2 - Silicon Carbide

Essential Electronic Materials: Part 3 - Germanium

Essential Electronic Materials: Part 4 - Gallium Compounds

Essential Electronic Materials: Part 5 - Carbon-Based Materials

Essential Electronic Materials: Part 6 - Conductive and Insulating Materials

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento