Muffle Furnaces: High-Temperature Materials Over 1800°C

Introduction

A muffle furnace is an important tool used in many industries and laboratories for high-temperature heat treatments. It heats materials within a clean and controlled environment without direct contact with the heat source. These ovens are widely used because they maintain constant temperatures and can be applied to a variety of tasks. In this article, we explain what a muffle furnace is, identify its primary components, and describe its typical applications.

What is a Muffle Furnace?

A muffle furnace is a high-temperature oven that heats materials in an insulated chamber so that they do not come into direct contact with the heat source. Traditionally, heat was produced by combustion in muffle furnaces, but modern versions use electric heating elements embedded in the walls of the furnace. These elements allow precise control of the heating process, thereby making the furnace suitable for various high-temperature applications.

Further reading: Introduction to Heating Furnaces: Principles, Types and Applications

What is the Primary Component of a Muffle Furnace?

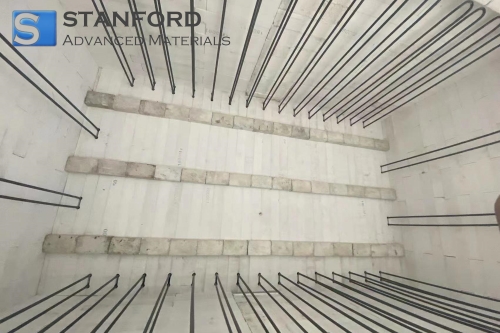

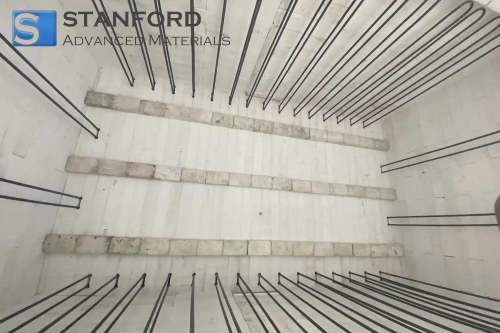

--The Isolated Chamber

The most important component of a muffle furnace is its insulated chamber or muffle. This chamber separates the materials from the heating elements, enables indirect heating, and prevents contamination. The chamber is usually made from high-temperature materials designed for durability and insulation.

The following materials are frequently used:

- Ceramics:

Ceramic materials are suitable for the construction of insulating chambers. Ceramic materials such as aluminium oxide or zirconium oxide are known for their thermal stability, chemical inertness and resistance to wear. These properties enable ceramic materials to withstand prolonged heat exposure while minimising the risk of contamination during sensitive processes.

- Refractory Bricks:

Refractory stones are another common choice for constructing the insulated chamber. These stones are designed to endure temperatures often above 1 800 °C without cracking or losing their structural integrity. Refractory materials typically comprise compounds such as aluminium oxide, silicon dioxide or magnesium oxide. The bricks contribute to heat retention within the chamber and thereby reduce energy consumption.

- Additional Insulating Materials:

Some advanced muffle furnaces may use supplementary insulating materials such as fibreglass mats or insulation boards to further enhance thermal efficiency.

-Heating Elements

Heating elements generate and maintain the high temperatures required for various industrial and laboratory processes. In modern muffle furnaces, these elements are typically electric and are embedded in the furnace walls to ensure even and precise heat distribution within the insulated chamber.

Frequently used materials for heating elements:

- Kanthal (iron–chromium–aluminium alloy):

Kanthal is a popular material for heating elements in muffle furnaces. This iron–chromium–aluminium alloy (FeCrAl) can withstand temperatures of up to approximately 1 400 °C. When heated, it forms a protective layer of aluminium oxide on its surface, which prevents further oxidation and decomposition, thereby extending the element’s lifetime.

- Silicon Carbide (SiC):

Silicon carbide is another material frequently used for heating elements in muffle furnaces, especially in applications requiring temperatures up to 1 600 °C. Heating elements made of SiC are known for their excellent thermal conductivity, which allows efficient heat transfer to the furnace chamber. Furthermore, SiC heating elements are highly resistant to oxidation and corrosion.

- Molybdenum Disilicide (MoSi2):

Molybdenum disilicide is a high-performance material used in heating elements for extreme temperatures, typically up to 1 800 °C or higher. MoSi2 elements maintain their structural integrity at high temperatures and are resistant to oxidation and decomposition. When heated, a protective silicon dioxide layer forms, which prevents further oxidation.

- Additional Heating Element Materials:

Some specialised muffle furnaces may utilise other advanced materials for heating elements, for example, graphite for applications that require temperatures above 2 000 °C, or Nichrome (a nickel–chromium alloy) for lower temperature ranges and cost-sensitive applications.

Where is a Muffle Furnace Used?

Muffle furnaces have diverse applications. Some common uses include:

- They are frequently employed for the heat treatment of metals and ceramics to modify their properties through controlled heating and cooling cycles.

- In chemical analysis, they are used for ashing to determine the content of inorganic substances.

- Muffle furnaces are used for calcination, that is, the thermal decomposition of compounds such as limestone at high temperatures.

- They are used for thermal testing in sectors such as aerospace and the electronics industry to assess material behaviour under stress.

- They are also indispensable for sintering, annealing and crystal growth in various high-technology applications.

How to Find a Reliable Supplier for Muffle Furnaces?

Finding a reliable supplier for muffle furnaces is crucial for the efficiency, safety and longevity of the devices. The following factors should be considered:

- Reputation and Experience: Select suppliers with a proven track record. Stanford Advanced Materials (SAM) has almost two decades of experience and offers over 3 000 advanced materials for various industries.

- Customised Options: The industry has specific requirements. Stanford Advanced Materials provides customisable muffle furnaces suitable for small laboratory tests or large industrial processes.

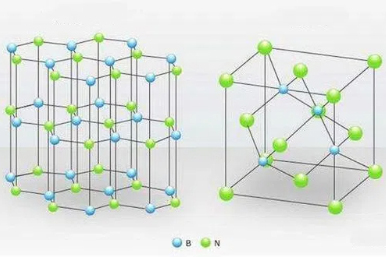

- Material Quality: The performance of a furnace depends on the materials used. SAM offers furnaces with heating elements made from molybdenum disilicide and insulated chambers made from zirconium oxide, which are suitable for temperatures exceeding 1 800 °C.

- Technical Support and Maintenance: A reliable supplier should provide expert support. Stanford Advanced Materials delivers skilled services in machining, cutting, microfabrication and customised manufacturing for a range of materials and components.

Conclusion

Muffle furnaces play a critical role in high-temperature processing across various sectors, ranging from the heat treatment of metals to conducting sensitive laboratory tests. When selecting a furnace for your requirements, it is important to understand key components such as the insulated chamber and the heating elements. Equally important is choosing a reliable supplier who offers customisation, technical support and high-quality materials so that the furnace meets your operational requirements. By focusing on these aspects, you can secure a muffle furnace that delivers long-term value and consistent performance for your applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento